Powder Coat Oven is indispensable in aerospace component finishing. The aerospace industry demands the highest standards of quality and durability for its parts. The Powder Coat Oven is used to cure powder coatings on components such as aircraft landing gear, engine housings, and fuselage panels. It operates at extremely precise temperatures and with strict process controls. For example, when coating landing gear, the Powder Coat Oven ensures that the powder coating is cured to a hardness and thickness that can withstand the intense forces and corrosive environments experienced during takeoff, landing, and flight. The Powder Coat Oven's ability to maintain a uniform temperature throughout the curing process is critical for ensuring the integrity of the coating. This results in components that have enhanced resistance to wear, corrosion, and thermal stress. With the Powder Coat Oven, aerospace manufacturers can produce parts that meet the stringent safety and performance requirements of the industry, contributing to the reliability and safety of air travel.

Title:Powder Coat Oven in Aerospace Component Finishing

Link:http://www.hpowdercoating.com/industrynews/show/301.html

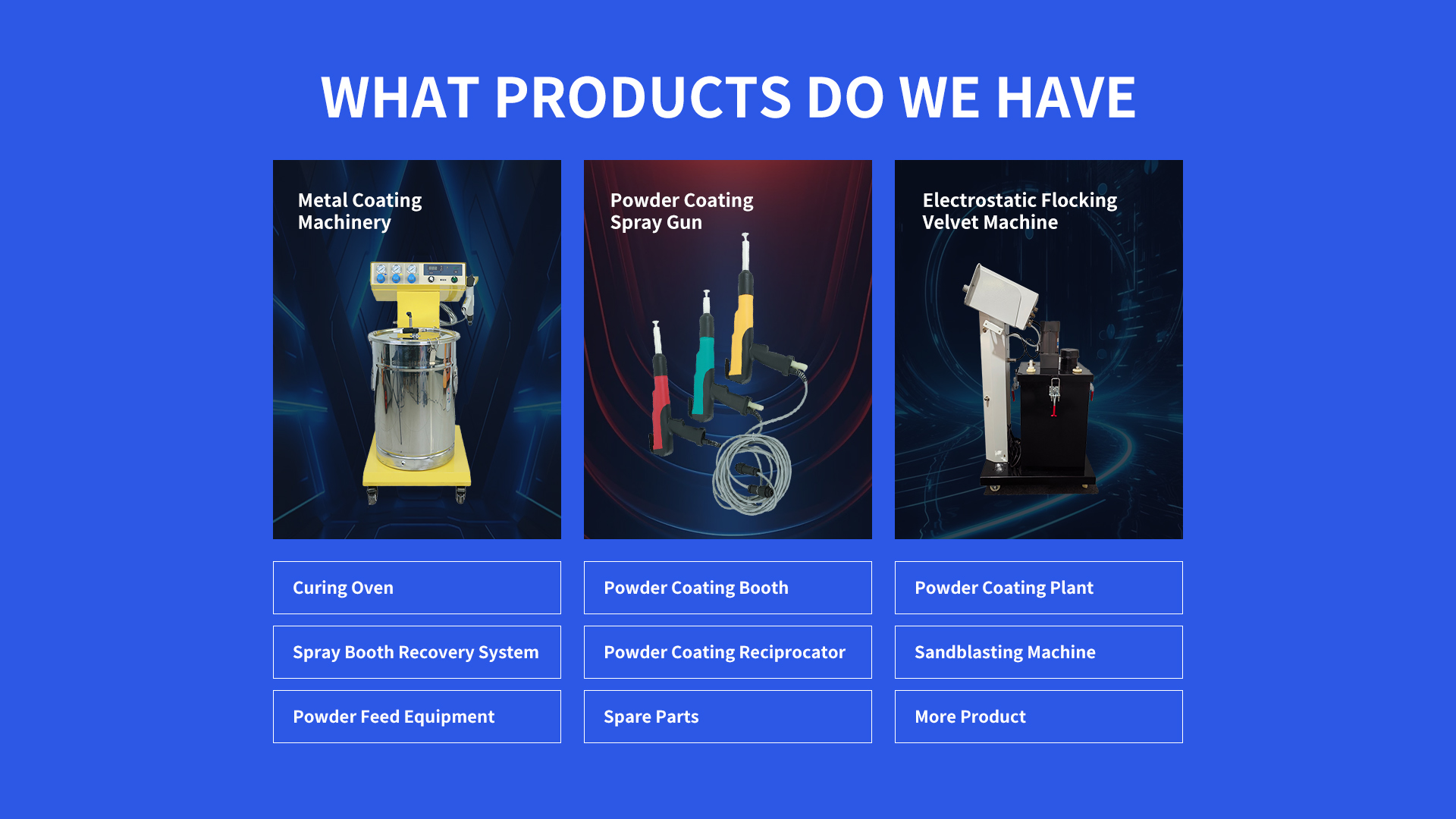

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com